JCB Electronic Service Tool diagnostic interface is used for fast and effective fault finding, check maintenance standards, see if the machine has been abused, view and change machine set up data, flash ECUs with the correct data files. You can resetEMShours, edit speed limiters and use other functions what require special unlock.

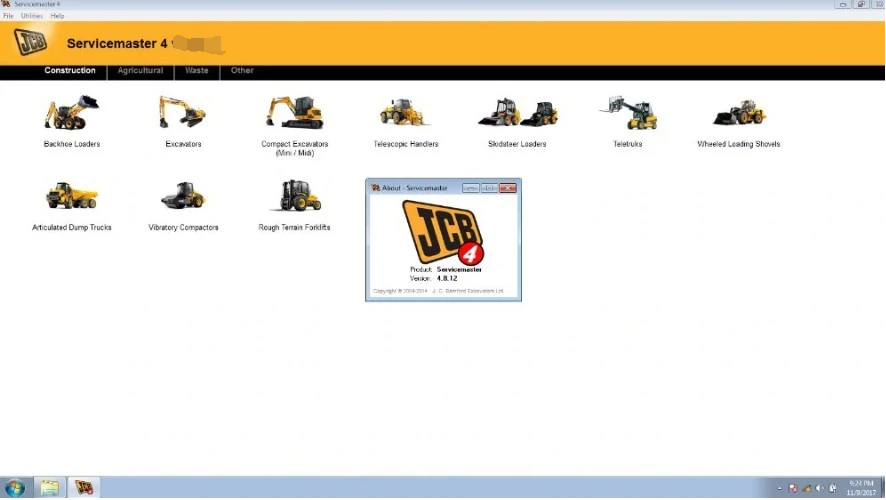

JCB Service Master is a gateway application allowing a large number of Vehicle Support Applications to be linked using one familiar interface. The interface acts as a graphical tool for selecting the target vehicle from a groups of Vehicle Families and triggering the particular Service Tool Application desired. This removes the need for a user to ‘remember’ every individual service tool available and select which one if intended for a particular machine.

The JCB Service Master also provides several key features that will accompany all JCB projects, a Multi Language editing tool that provides a means of individual text string translation for all JCB Applications and a means to select a localised language translation for the each JCB Application.

JCB Electronic Service Tool Highlights:

1. Reads fault codes and ranks them in order of importance.

2. Calibrates, parameterize ECM and program blocks.

3. Conducts dropping service intervals.

4. Compatible with software JCB Service Master 4 (2019).

5. It works with CAN protocol in OBD II system.

6. It is provided with instructions for use, repair and diagnostics of vehicles JCB engines and Isuzu, Deutz, Cummins.

7. Full original JCB repair and service manuals and bulletins

8. JCB spare parts for all markets

9. Programming special parameters (order separately)

10. Supported languages: English, German, Spanish, French, Italian, Portuguese.

JCB Service Tool Supported Models and Engines

Agricultural models:

1. Fastrac Tractors (2000-3000, 3000 Series

2, 3000 Series 3, 3000 Series 4, 7000 Series, 8250 Series 1, 8250 Series 2, 8000 Series 3), 2. Telescopic Handlers (2007-, 2007+, Tier 4, 525-60 Compact Loadall),

3. Wheeled Loading Shovels (Large, Large 2012+, Compact (Tier 4 CWLS), Medium (411, 413 ,417, 418S Tier 4i)

4. Telemasters (TM180/220, TM310, TM320)

Construction models:

1. Backhoe Loaders,

2. AMS/DECU Machines (Tracked (JS/JZ/JZ70), Wheeled),

3. Compact Excavators (Mini/Midi) (801-8065, 8080-8085,65R1-86C1),

4. Telescopic Handlers (2007-, 2007+, Tier 4, 525-60 Compact Loadall),

5. Skidsteer Loaders (Robot, Other), Teletrucks (Tier 4),

6. Wheeled Loading Shovels (Large, Large 2012+, Compact (Tier 4 CWLS), Medium (411, 413 ,417, 418S Tier 4i)),

7. Telemasters (TM180/220, TM310, TM320)),

8. Articulated Dump Trucks, Vibratory Compactors (Tier 3, Interim Tier 4, VMT380/430),

9. Rough Terrain Forklifts (Tier 2/3 RTFL, Tier 4 RTFL), 10. Teletruks (Tier 4).

Waste models:

Telescopic Handlers (Tier 3, Tier 4).

Engines:

1. Dieselmax and Dieselmax 672 (IPU, OEM Base, G Drive),

2. Ecomax (IPU, OEM Base, G Drive), Kohler TCR Engine.

3. Generators: G46X/QX, G141X/QX, G165S/QS, G200S/QS, G220S/QS.

JCB Electronic Service Tool Software Display:

Packing List

1 x JCB Electronic Service Tool Diagnostic Interface

1 x 9 Pin and 6Pin Cable

1 x USB Cable

1 x JCB Service Master Diagnostic Software CD

Leave a Reply